The Environmental Protection Agency lists the average life span of a cell phone as 18 months. At this rate, 426,000 cell phones are thrown away each day in the US alone. Unfortunately, modern day cell phones can and do last much, much longer. We need a design and system that takes into account a responsible method for the eventual disposal of these devices. We also need an alternative to the enormous amounts of energy consumed in the creation of these products. We need to rethink how cell phones are made!

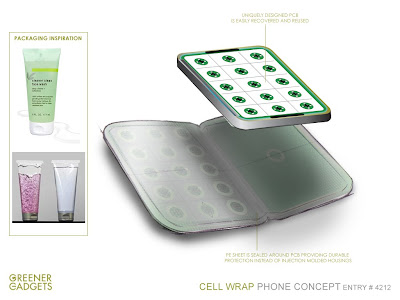

Cell Wrap rethinks the design of modern day cell phones taking inspiration from a packaging point of view. It provides a durable, protective cover that finally takes into account the lifespan of today’s cellular phones. Cell Wrap uses a similar method of packaging as in collapsible tube containers commonly used for storing gels, liquids, and cosmetics that can be found in any home. This type of cover requires no need for hardware and minimal assembly time compared with traditional plastic housings. However, the most substantial ‘Green’ impact this concept offers is the quantity of energy saved by the simple sealing of the wrap around internal components. Enormous amounts of energy are consumed in the design process, molding infrastructure, finishing chemicals, and assembly processes required of standard injection molded phones.

Cell Wrap provides a simple design that creates a small, easy-to-use phone free of unwanted features. Most importantly, it provides piece of mind, by creating a product that stays true to its original intent while addressing issues of the products ecosystem. This new way of doing things is also carried over in the way the phone is used. To keep size down to a minimum, the lead-free LCD screen is side mounted on the PCB Board leaving only the keypad on the front face of the phone. The wraps side finish is done in ultra clear for reading this screen. The overall design allows for a small carbon footprint, while still offering protection of internals with various design possibilities in the form of graphics and surface textures on the wrap.

The wrap is created from a large percentage of post consumer recycled Polyethylene (PE). This plastic provides the flexible properties necessary for tactile feedback from domed pucks on the keypad. PE is also used for its reduced leaching potential in landfills, dioxin formation during burning, and minimal costs needed for recycling. However, Cell Wraps end of life cycle is what makes it truly innovative. When the user is finished with their phone, the pouch can be sliced open and easily removed. This sleeve can be broken down to a flat piece taking up minimal space and then further recycled. The internal PCB board is then mailed away in an envelope provided by the manufacturer for used in similar phones.

No comments:

Post a Comment